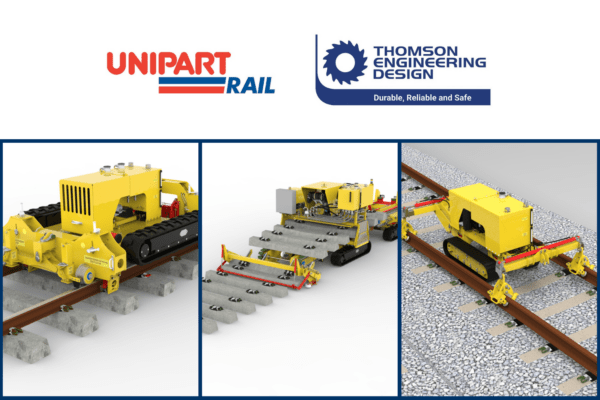

April 2024 – Unipart Rail today announces the launch of a new range of innovative rail construction, maintenance and renewal machines.

April 2024 – Unipart Rail today announces the launch of a new range of innovative rail construction, maintenance and renewal machines.

Designed to address the challenges faced by the global rail industry and revolutionise traditional methods of working, these cutting-edge machines are poised to increase safety, drive performance improvement & efficiency, accelerate project timescales and significantly reduce costs.

Developed in partnership with strategic partner Thomson Engineering Design Ltd, the key features of these groundbreaking machines include:

- Cost Savings: With lower capital investment and operational costs, in addition to reduced labour requirements and enhanced productivity, these machines enable significant cost savings for rail operators.

- Efficiency: By automating repetitive tasks and optimising workflows, these machines drastically reduce the time required for rail projects, leading to increased efficiency and faster project completion.

- Advanced Technology: Incorporating state-of-the-art digital technologies, such as automation, these machines offer unparalleled precision and accuracy in rail maintenance and renewal tasks, leading to high quality, sustainable infrastructure and safer working environments.

- Versatility: Designed to handle a wide range of tasks, from track renewal to ballast maintenance, these machines offer versatility and adaptability to meet the diverse needs of the global rail industry.

Neil McNicholas, Managing Director, Unipart Rail commented: “We are extremely excited to introduce this range of game-changing machines to the global rail industry, alongside our partner Thomson Engineering Design. These transformative solutions represent a new era for the industry, delivering unparalleled efficiency, enhancing safety, accelerating project timescales, and ultimately saving money for our customers.”

The new machine range includes:

- Sleeper Layer: Providing delivery rates of up to 1000 sleepers/ties per hour, and offering a variety of options including automatic steering, remote condition monitoring and diagnostic support, the Sleeper Layer offers a complete step change for the track renewals industry.

- Rail Handler: A versatile, multi-purpose machine offering a variety of applications and benefits for installing, removing and transposing rails.

- Rail Clipper: A unique self-propelled, road-rail clipping machine with applications in rail maintenance and track renewals operations.

Traditionally, the industry has relied on specialist on-track plant equipment to deliver rail renewals. Whilst there are benefits to these methods, they do pose multiple challenges in terms of cost, flexibility, logistical implications, resource, skills, and environmental impacts.

However, with the introduction of Unipart Rail’s new range of machines, the industry is set to undergo a transformative shift towards streamlined operations and enhanced productivity.

To propel the advancement and expansion of the product range, Unipart Rail and Thomson Engineering Design Ltd are also developing a transformative solution for global rail panel handling – MoRPH (Mobile Rail Panel Handler). The funding for which will be provided by the Department for Business and Trade and Innovate UK, in partnership with the Global Centre of Rail Excellence (GCRE).

In addition, Unipart Rail also delivers a range of material handling solutions which enhance traditional rail project activities, enabling rail operators to proactively address maintenance challenges and maximise operational uptime.

Dan Barnard, Operations Director, Thomson Engineering Design Ltd, said: “Our collaboration on this new range of machines further enhances and strengthens our partnership with Unipart Rail. We are proud to be working together to introduce a new approach to the rail industry and a suite of solutions which will optimise and enhance rail renewal and maintenance projects across the world.”

To learn more about our new product range visit our new webpage here.