Get in touch

Read more on our sustainable operations solutions, including green warehousing, and how these steps can be personalised to your organisation’s decarbonisation goals.

Companies are grappling with soaring energy expenses, witnessing a staggering average surge of 180% in out-of-contract gas rates and 130% in out-of-contract electricity rates since August 20211. But for firms aiming to reduce expenses in their existing supply chain structures, they need to prioritise their overall carbon footprints to improve profitability.

While companies may know how much energy they consume from rising monthly bills, only a limited number will know the reason for their consumption rates. While 93% of companies must halve their carbon emissions to meet net zero goals, barely any have true control. Only 12% of companies rate their ongoing sustainability efforts as “extremely successful”.

But what can companies practically do to reduce carbon emissions? One way to address both reduction in expenses and improving carbon footprints is with ‘green warehousing’.

With the UK’s net-zero carbon emissions needing to be met by 2050, all large UK businesses have a legal requirement to comply with these to support efforts2.

Focusing on an area like green warehousing, means updating warehouse operations and infrastructure to minimise energy consumption, harness sustainable energy sources, and reduce the generation of non-recyclable waste in warehouse operations3.

Embracing green logistics in warehousing operations can significantly boost business productivity and profitability. Integrating sustainable practices into warehouse management can offer return on investment, along with long-term global benefits.

Recognising the need for our customers to reduce their carbon footprints, in May 2024, Unipart launched our Circular Economy initiative, to make the transition to green warehousing easier to navigate.

Unipart has devised a sustainable operations solution to decarbonising existing warehouses. To do this, we address five key areas we think will have the most impact for businesses:

Effective energy management and monitoring are essential to ensuring sufficient granularity, enabling consumption reduction, and Unipart has developed an insight tool that has provided up to 25% in energy savings for sites4.

Effective energy management and monitoring are essential to ensuring sufficient granularity, enabling consumption reduction, and Unipart has developed an insight tool that has provided up to 25% in energy savings for sites4.

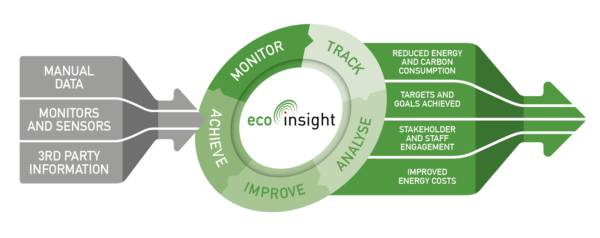

Launched in May 2023, Eco Insight provides automated real-time energy and water consumption data across multiple utilities and inputs, collating the data into a single visual dashboard.

Eco Insight identifies energy consumption by appliance and area on site, tackling energy monitoring challenges and assisting in forecasting capabilities, providing real-time data when modelling various energy reduction strategies.

Energy monitoring solutions are the first step in reducing the carbon output of new and existing buildings, as companies can easily identify high-consumption assets.

The tool adds value for businesses through:

One of Europe’s leading media and entertainment companies has incorporated our waste-reduction solutions. Since 2012, Unipart Logistics has prevented 100% of their engineer waste from reaching landfills by delivering recycling and reuse solutions to incorporate zero-landfill solutions on returns.

Unipart Logistics successfully removed more than 610 tonnes of CO2 emissions (equivalent) from the company’s annual distribution emissions and used zero plastic on any product or packaging, down to paper tape. We also recycled 2,270 tonnes of waste for the company last year, and we can recycle a portfolio of over 16,000 of their product lines.