Great British Manufacturing

Unipart is at the heart of British manufacturing, bringing innovative products to reality.

Our core engineering and manufacturing capabilities are built on decades of industry experience and continuous improvement as a partner to a number of the world’s leading automotive, aerospace, rail and technology manufacturers and tier 1 suppliers.

As global manufacturing industries focus on the transition towards net zero, and the integration of new technologies, Unipart is applying expertise in automation, joining technology, safety critical processes, supply chain management and design-for-manufacturing solutions to complex challenges across the end-to-end engineering and manufacturing supply chain.

Our advanced capabilities, from smart manufacturing and optimised tooling, to precision assembly fixtures and polymer and composite solutions are setting new quality, production and efficiency standards for manufacturing industries.

Creating the next generation of engineers

Unipart is preparing the next generation of engineers through a unique collaboration with Coventry University.

In 2014, this collaboration launched The Institute for Advanced Manufacturing and Engineering (AME) creating a first-of-its-kind ‘Faculty on the Factory Floor’. This is a unique learning and development environment producing the next generation of highly-skilled engineers and leaders.

Over 400 students have graduated from the AME with a BEng or MEng in Manufacturing and Engineering, more than £110m of Research and Development projects have been completed, and more than £500m of economic value has been generated for UK industry.

Following a recent £6m investment, the AME opened its state-of-the-art expansion, boasting an additional 2000 sq metres of space featuring new teaching and research facilities, with digital innovation, robotics and functional materials laboratories at its heart.

Click the buttons below to find out more about the AME and its recent £6m investment.

Investment in British manufacturing and building resilience

In August 2024 Unipart acquired Formaplex Technologies, one of the few remaining injection moulding specialists in the UK, and a key supplier of high-quality finish polymer and composite parts for customers, including McLaren Automotive.

This acquisition, now rebranded Unipart Polymer and Composite Solutions, shows Unipart’s commitment to investing in British Manufacturing and growing the UK supply chain.

Click the buttons below to read the full press release and watch a video.

Building new manufacturing supply chains (electrified powertrains)

Unipart Manufacturing is set to play a key role in Project PULSE (Power electronics Upscale for Localisation and Sustainable Electrification), an £11 million initiative funded by the UK government through the Advanced Propulsion Centre (APC) announced this year.

As a key partner in this consortium, Unipart will establish a flexible power electronics manufacturing capability at its Beresford Avenue manufacturing site in Coventry. By 2030, this project will create or safeguard 159 jobs in the UK and, importantly, will save 1.2million tonnes of CO2 every year.

Click the button below to read more.

EV solutions

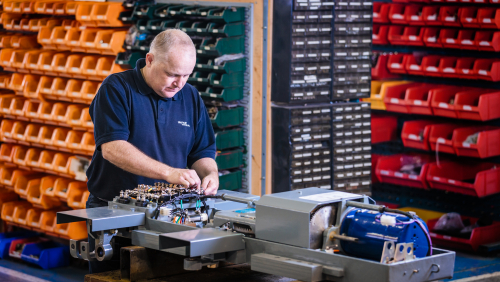

Providing EV battery solutions from manufacturing, logistics, transportation, storage and lifecycle management, Unipart is uniquely positioned to support its customers manufacturing and logistics needs. Unipart’s core capabilities are built on decades of industry experience and continuous improvement as a Manufacturing Partner for the world’s leading automotive manufacturers and Tier 1 suppliers.

As industry transitions to net zero, Unipart is solving the complex manufacturing challenges of tomorrow by applying expertise in automation, joining technology, safety critical processes, supply chain management and design-for-manufacturing to the production of electrified powertrain components and systems.

Click the left button to read more about Unipart’s range of EV solutions.

Click on the right button to read how MetLase, a Unipart company, developed an EV battery assembly fixture to enable Hyperbat, one of the UK’s leading manufacturers of high-performance EV battery packs and supplier of batteries for the world’s most powerful production car, to optimise complex assembly operations.

Hyperbat's battery systems

Hyperbat is an experienced UK battery system manufacturer, partnering with customers to industrialise battery technology, delivering both battery development and series production.

At its core, Hyperbat is an established Tier 1 supplier of bespoke, build-to-print and off-the-shelf battery systems. With deep capability and experience, originating from a joint venture between Fortescue Zero and Unipart, Hyperbat provides unique customer solutions supported by industry leading processes.

Click the button below to find out more.

Celebrating Rail Forum’s Made In Britain campaign

In June 2024 the Rail Forum, a national industry body, launched a ‘Made in Britain’ social media initiative to provide an opportunity for its members involved in manufacturing to highlight their capability, capacity and processes.

Unipart was proud to support the UK rail industry and the Rail Forum in celebrating the Made In Britain campaign, taking the opportunity to highlight its innovative, high quality, high performance range of replacement railway equipment designed to help deliver and sustain the world’s best rail operations.

Unipart Rail’s manufacturing services include specialist component and systems manufacture, new and legacy manufacturing, and a complete maintenance, repair & overhaul programme in addition to a range of offsite factory testing solutions.

Click the button below to find out more.