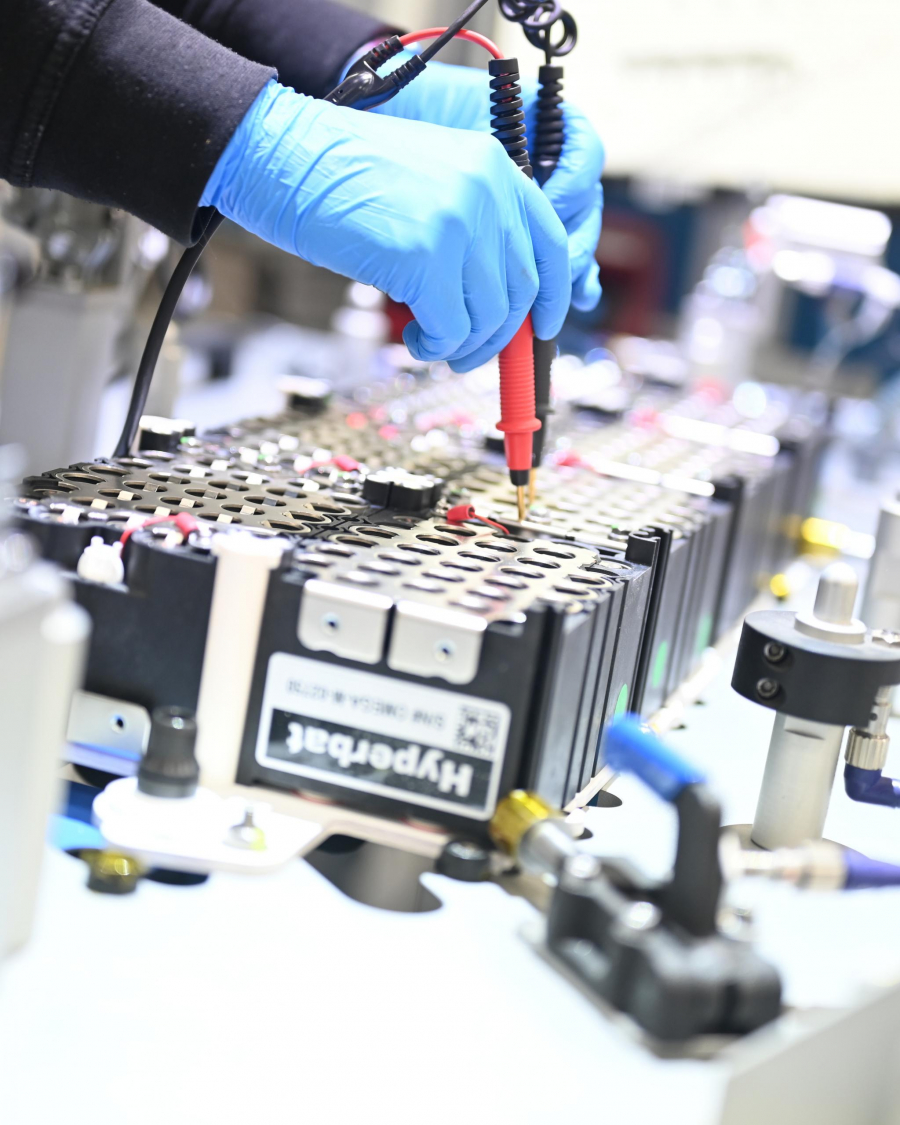

EV battery assembly production cycle time reduced by 70%

70%

Reduction in production cycle time

The Impact

MetLase’s bespoke solution allowed Hyperbat to transition from manual EV battery assembly to automated assembly for the first time, increasing volume and maintaining precision quality in the process.

The fixtures enabled accurate, repeatable component assembly, delivering:

- 70% reduction in production cycle time

- 300% increase in through-put

- Significant reduction in missed welds

- Full project completion in just 10 weeks

The fixtures worked for the first time without issue. There was no visible beam clipping at the extremities of the PFO deflection, and there was good clamping force – these are world-class fixtures and a step forward. The production cycle time has been significantly reduced, leading to a 300% increase in throughput.”

"It’s very rare that manufacturing processes can be improved to this extent; this simply would not have been possible without MetLase.Dr Nicholas Longfield, Welding Engineering Manager, Hyperbat

Contact us now

Get in touch and tell us about your engineering and manufacturing challenges.