December 2020 – Electric vehicle batteries are set to dictate the agenda for the original equipment manufacturers over the next few years.

December 2020 – Electric vehicle batteries are set to dictate the agenda for the original equipment manufacturers over the next few years.

Unipart Logistics Automotive Director Richard Hankinson discusses the rapid rise of electric vehicles and the challenges facing manufacturers when it comes to the battery.

How does electrification fit into the mega trends driving the automotive industry?

The mega trends driving the industry are ‘autonomous, connected, electric and shared’ mobility automotive technology, known collectively as ACES.

Electrification has already begun in earnest and will continue apace as environmental awareness drives government carbon neutral agendas, municipal zero-emissions zones and consumer demand.

Connected vehicles will be the next big ticket item. Over time outright car ownership will reduce as consumers move away from being tied to an asset which statistically does nothing but sit on your driveway 80 percent of the time. Just as consumers used to buy vinyl and CDs but now pay to stream music rather than own it, vehicles will increasingly be shared between users using internet technology.

Then as connectivity achieves greater sophistication, mobility’s next milestone will be fully autonomous vehicles. Tech giants have already made well publicised forays into this field, which when perfected will lead to fewer collisions, and less wear and tear. All of which will mean the demand for new vehicles and for aftermarket parts will dramatically reduce over the next decade.

Why are consumers increasingly turning towards EVs?

Traditional barriers to electric vehicle ownership are quickly being eroded away. The cost of new EVs is coming down, range anxiety is diminishing as new models go further on a single charge, and the charging network itself is growing every day.

Even through the Covid pandemic, which has hit the automotive industry hard, EV sales continue to rise. Now the world has seen a glimpse of roads without the noise and pollution of internal combustion engines, many see the pandemic as a chance to hit ‘reset’ and focus on sustainable mobility. The UK market in lockdown reflects this: EV sales have bucked the trend of the steep decline in petrol and diesel sales during the pandemic and are actually higher than in the same period last year.

In the race to meet consumer demand and keep up with the competition, automotive manufacturers (commonly known as original equipment manufacturers or OEMs) are focused on the front end of the market, producing more new electric vehicles than ever before. The market is set for an onslaught of them over the next three years.

The next hurdle is how they provide aftermarket support to this flood of new technology through a network of dealerships and other partners rooted in the internal combustion engine sector.

Why is the battery life cycle such a big challenge for EV manufacturers?

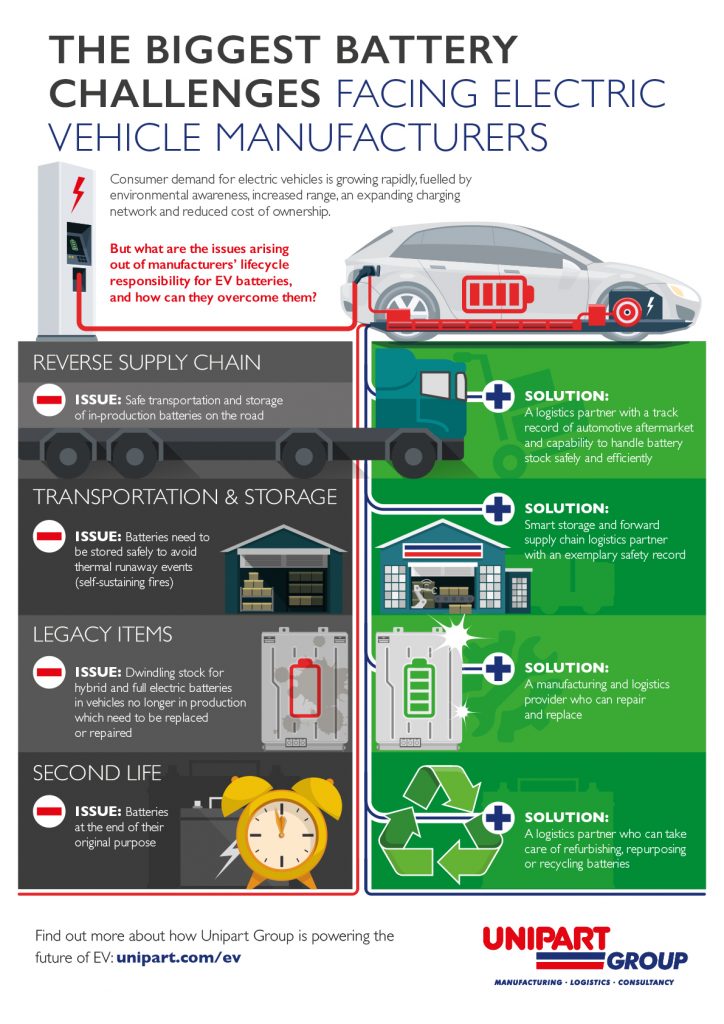

EV manufacturers are responsible for the whole life of the batteries in the vehicles they produce, which means when those batteries fail or come to the end of their life, the OEM needs to find a way of either repairing them, reusing them or recycling them.

With OEMs investing so much into this technology and rapidly producing greater quantities of batteries, a battery end-of-life solution is not only a vital piece of the EV jigsaw, but also still the missing piece. A circular economy needs to be created, supported by both business and government.

The raw materials needed to build a battery aren’t inexhaustible, so OEMs must find a way to reuse or recycle them.

EV legacy items are one example of this looming problem. Where an EV model has passed out of production, how does the OEM continue to replace and repair failed batteries from dwindling stocks? They need a partner with automotive manufacturing and aftermarket logistics experience and capability.

What will EV manufacturers be mindful of in 2021?

While EV sales have continued to rise in 2020, the market is not totally immune to the pandemic, and global supply chain disruption will continue to be a concern.

In the UK in particular, supply chain apprehensions are exacerbated by the spectre of Brexit inching ever closer. Just-in-time production was pioneered and refined by the automotive industry, and as a result the UK’s entire supply chain is based on frictionless trade. How is that affected by potential border delays arising out of the UK’s exit from the EU?

One consequence of Brexit planning on the automotive industry is storage, or more poignantly lack of storage. With details unclear of how the post-Brexit world will look, OEMs’ mitigation plans revolve around keeping additional stock in case of supply chain disruption. EV manufacturers are looking for logistics partners who are agile and flexible. Nowhere is this more relevant than EV battery storage.

Why is storage so important for EV batteries?

Why is storage so important for EV batteries?

High-voltage lithium ion batteries have a risk of thermal runaway which can lead to batteries starting their own self-sustaining fire. This would have devastating consequences for large quantities of assets. Storing batteries safely and correctly will reduce this risk.

At the moment the industry overcomes this issue by locating expendable storage units well away from other buildings.

Ironically, while regulation surrounding battery life cycle is a worry for OEMs, battery storage regulation is relatively open as the UK wants to remain competitive with the world’s biggest EV producer China. In some ways insurance premiums can be a bigger influence than regulation.

Smart storage is the next big trend. Unipart was involved in a UK Government research programme called Project Detain, which sought to identify how storage conditions could be controlled digitally using sensors to improve safety (and hopefully the confidence of insurers). As smart storage becomes more prevalent, a better network of EV battery storage should make for a stronger supply chain.

Who should EV manufacturers be looking to partner with to solve battery challenges?

Knowledge and capability in automotive logistics is paramount. EV manufacturers need to find a partner who understands both the forward and reverse supply chain, with heritage in the automotive industry but who is also already working with the big brands on their electrification.

Unipart Logistics has a strong track record in the end-to-end supply chain, not just in automotive but also in the technology sector. We have been working with premium telecoms consumer brands for years, reusing and recycling batteries in mobile devices which often contain many of the same rare metals as EV batteries.

When it comes to the aftermarket, from in-production EVs to legacy items, OEMs need a partner with cutting-edge expertise in EV battery manufacture.

Hyperbat is Unipart Manufacturing’s joint venture with Williams Advanced Engineering, and is leading the way in high-performance EV batteries in automotive and other sectors. Recently, Hyperbat was part of a Unipart initiative to develop zero-emission rail technology which won a share of £9.4m Department for Transport and Innovate UK funding.

Finally, a strong safety record is crucial. Unipart has won more British Safety Council Swords of Honour than any other company in its sector. EV technology is in the ascendance but needs a safe pair of hands to thrive.

This article was first published in The Engineer magazine’s Tech Trends 2021.